I would like to know more about:

As a person conducting a business or undertaking (PCBU), you must eliminate or minimise risks in the workplace from airborne contaminants so far as is reasonably practicable. In many cases, compliance with the regulations can be achieved through the application of basic, well-known exposure controls. This could include controls such as eliminating the process that is causing the hazard (e.g. removing ‘on-site’ cutting), or substituting hazardous substances with less harmful ones.

You must also ensure that workers or others at the workplace are not exposed to levels of airborne contaminants above their workplace exposure standard (WES) during the transition period ending 30 November 2026 and not above the workplace exposure limit (WEL) when it takes effect from 1 December 2026.

The WES/WEL is not the dividing line between a healthy and unhealthy work environment. Natural human biological variations and individual susceptibilities (such as a pre-existing medical condition) mean a small number of people may still experience adverse health effects from exposure to levels below the WES/WEL. As such, you must always eliminate the risk of exposure to airborne contaminants so far as is reasonably practicable. If you cannot eliminate the risk, minimise the risk so far as is reasonably practicable.

You may also have mandatory WHS duties in relation to health and air monitoring for airborne contaminants and the usage, handling and storage of hazardous chemicals, as well as specific duties in relation to crystalline silica, asbestos and lead.

As a person conducting a business or undertaking (PCBU), you must eliminate or minimise risks in the workplace from airborne contaminants so far as is reasonably practicable. To manage risks from airborne contaminants, you should follow the risk management process:

- Identify hazards

- Assess risks

- Control risks

- Review control measures

When working through the risk management process, you must also consult with your workers. By drawing on the knowledge and experience of your workers, you can make more informed decisions about how to carry out the work safely.

1. Identify hazards

To protect workers from being harmed by hazardous substances, you must first identify if there are any airborne contaminants at your workplace.

You can identify airborne contaminants in your workplace by:

- looking at your workplace, products and processes

- talking and consulting with your workers

- reading any labels and safety data sheets

- talking with your WHS regulator

- engaging a professional such as an occupational hygienist.

2. Assess risks

Once you have identified an airborne contaminant, you need to undertake a risk assessment to consider what could happen if your workers are exposed to the hazardous substance and the likelihood of it happening. A risk assessment will help you:

- identify which workers are at risk of exposure

- determine what sources and processes are causing the risk

- identify if and what kind of control measures should be implemented, and

- check the effectiveness of existing control measures.

3. Control risks

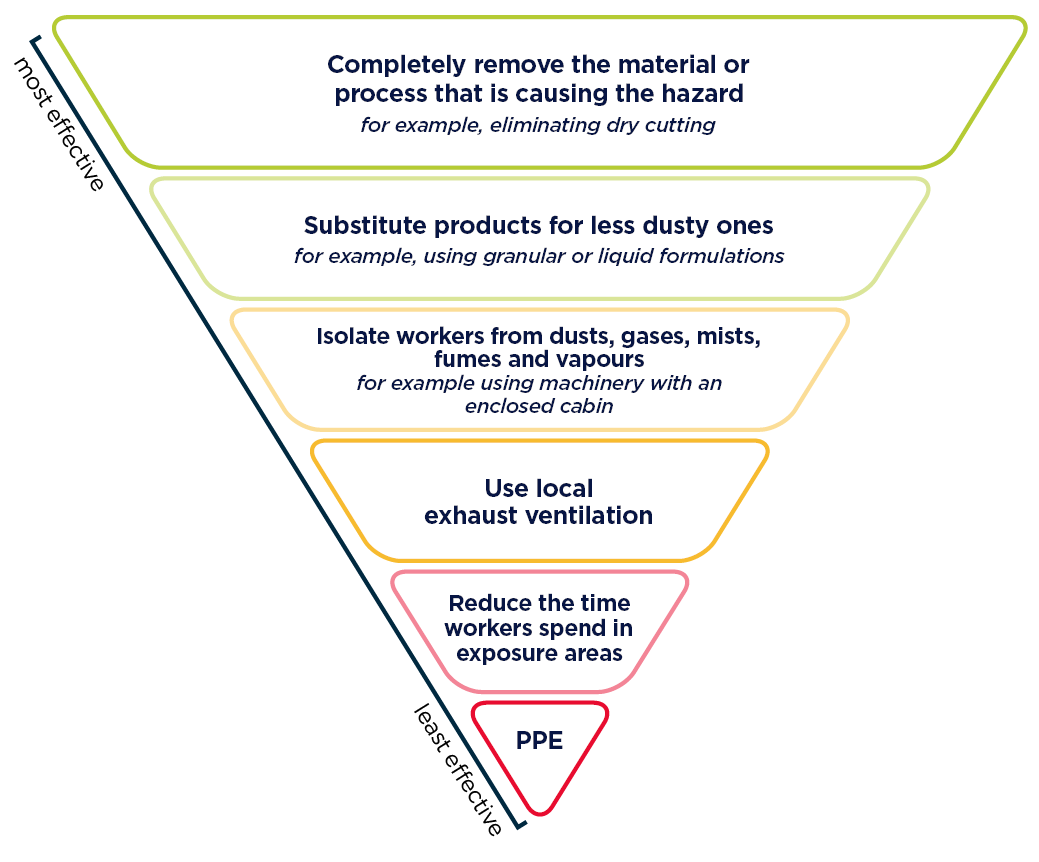

You should always aim to eliminate risks, as this is the best way to manage risks. Where this is not possible, you must minimise risks so far as is reasonably practicable.

Elimination

The most effective way to manage a risk is to completely remove the hazard from your workplace. This means eliminating the creation of hazardous dusts, gases, fumes and vapours. Examples of elimination controls can include:

- using products or materials that don’t contain the hazardous substance

- eliminating the need to undertake the task that releases the hazardous substance into the air.

In some cases, elimination might not be possible. Where this occurs, you must work through the hierarchy of risk control measures.

Examples of effective control measures for managing the risks of airborne contaminants

If you or your workers could be exposed to dusts, gases, mists, fumes or vapours, make sure you’ve implemented the right control measures.

Employers must ensure that exposure to airborne contaminants is as low as possible so workers don’t get sick.

Substitution

Substitution controls involve replacing the hazard with something safer:

e.g. using granular or liquid formulations instead of ones that produce dust.

Isolation

Isolation controls involve isolating the hazard from people:

e.g. completing the task that releases the hazardous substance in an enclosed, well-ventilated space that is separated from people.

Engineering

Engineering controls involve using a physical control measure, such as a mechanical device or process:

e.g. using dust suppression, local exhaust ventilation and on-tool dust extraction.

Administrative

If you’ve worked through the hierarchy of control measures and risk remains, you must minimise the risk by implementing administrative controls, for example:

- planning tasks to minimise the quantity of the hazardous substance being released into the air

- reducing the time workers spend in exposure areas

- establishing policies about working with the hazardous substance and clean up requirements

- installing signage alerting people of the risks involved and how to minimise them.

Personal protective equipment

Personal protective equipment (PPE), including respiratory protective equipment (such as masks), is one of the least effective control measures because it does not control the risk at the source. PPE should only be considered after implementing substitution, isolation, engineering, and administrative controls. You should use PPE to supplement higher-level control measures.

In some situations, higher-order control measures might not control the risk fully. In these cases, PPE must also be used.

4. Review control measures

Implementing measures for controlling airborne contaminants isn't a matter of simply "set and forget". You must regularly monitor and review your control measures to make sure they are still effective and are working as intended. If you’ve implemented measures to control dusts, gases, fumes, mists or vapours, you must review them:

- when the control measure is not effective in controlling the risk

- before a change at your workplace that is likely to give rise to a new or different health and safety risk that the control measure may not effectively control

- if a new hazard or risk is identified

- if the results of consultation indicate that a review is necessary, or

- if a health and safety representative requests a review.

After you review your control measures, if you have identified a new or changed hazard or risk that needs to be addressed, you should:

- go back through the risk assessment steps (identify and assess hazards, eliminate and control risks and monitor and review controls)

- consult with your workers, and

- implement new control measures to address the new or changed hazard or risk that you’ve identified.

Air monitoring involves measuring the level of an airborne contaminant in the breathing zone of workers using a personal sampler during their usual work activities, including routine breaks.

Air monitoring might be needed to make sure that your workers are not exposed to airborne concentrations of a substance above the workplace exposure standard. Results from air monitoring can also indicate how effective your workplace controls, such as ventilation systems, are operating.

Do I need to do air monitoring?

As a person conducting a business or undertaking (PCBU), you must do air monitoring to determine the concentration of an airborne contaminant at your workplace if:

- you are not certain on reasonable grounds if the airborne concentration of the substance at the workplace exceeds the exposure standard or exposure limit, or

- monitoring is necessary to find out if there is a risk to health.

Where air monitoring is required, it should be conducted after exposure controls have been put in place. In many cases, compliance with the regulations can be achieved through the application of basic, well-known exposure controls.

Air monitoring is carried out by a competent and experienced person such as an occupational hygienist with skills to carry out the monitoring and interpret the results.

The model WHS Regulations also have specific requirements for air monitoring when asbestos removal requires a Class A asbestos removal licence. More information can be found on air monitoring for asbestos in the model Code of Practice: How to safely remove asbestos.

If you are unsure whether air monitoring is required, consult an expert for advice.

Visit the Australian Institute of Occupational Hygienists website (www.aioh.org.au) to find a qualified occupational hygienist who may be able to help in your workplace.

Health monitoring involves using medical tests to monitor and protect a worker’s health because of exposure to hazardous chemicals.

It is not an alternative to implementing effective control measures according to the hierarchy of controls. Health monitoring provides information to you as a person conducting a business or undertaking (PCBU) about the control measures that are used at the workplace.

It lets you know if control measures are not effective or if a worker’s health is being affected by exposure to hazardous chemicals, so that action can be taken.

Health monitoring is carried out by or supervised by a registered medical practitioner (a doctor) with experience in health monitoring.

Do I need to provide health monitoring?

As a PCBU, you must provide health monitoring to workers if there is a significant risk:

- to worker’s health because of exposure to a hazardous chemical listed in table 14.1 of Schedule 14 of the model WHS regulations, or

- of exposure to another hazardous chemical (not listed in Schedule 14) and there are suitable testing methods available. Examples of such chemicals are cyclophosphamide, ethyl benzene and nickel.

Lead and asbestos have specific health monitoring requirements.

See the full list of Health monitoring guides.